About PGAS

World-class turbine/generator alignment—optical and laser—planned around your outage window, delivered to spec.

Our APPROACH

Here's What We Do Better For

The Power Generation Industry

Our breadth of experience and specialized training in turbine alignment is unsurpassed in keeping your plant running at peak performance.

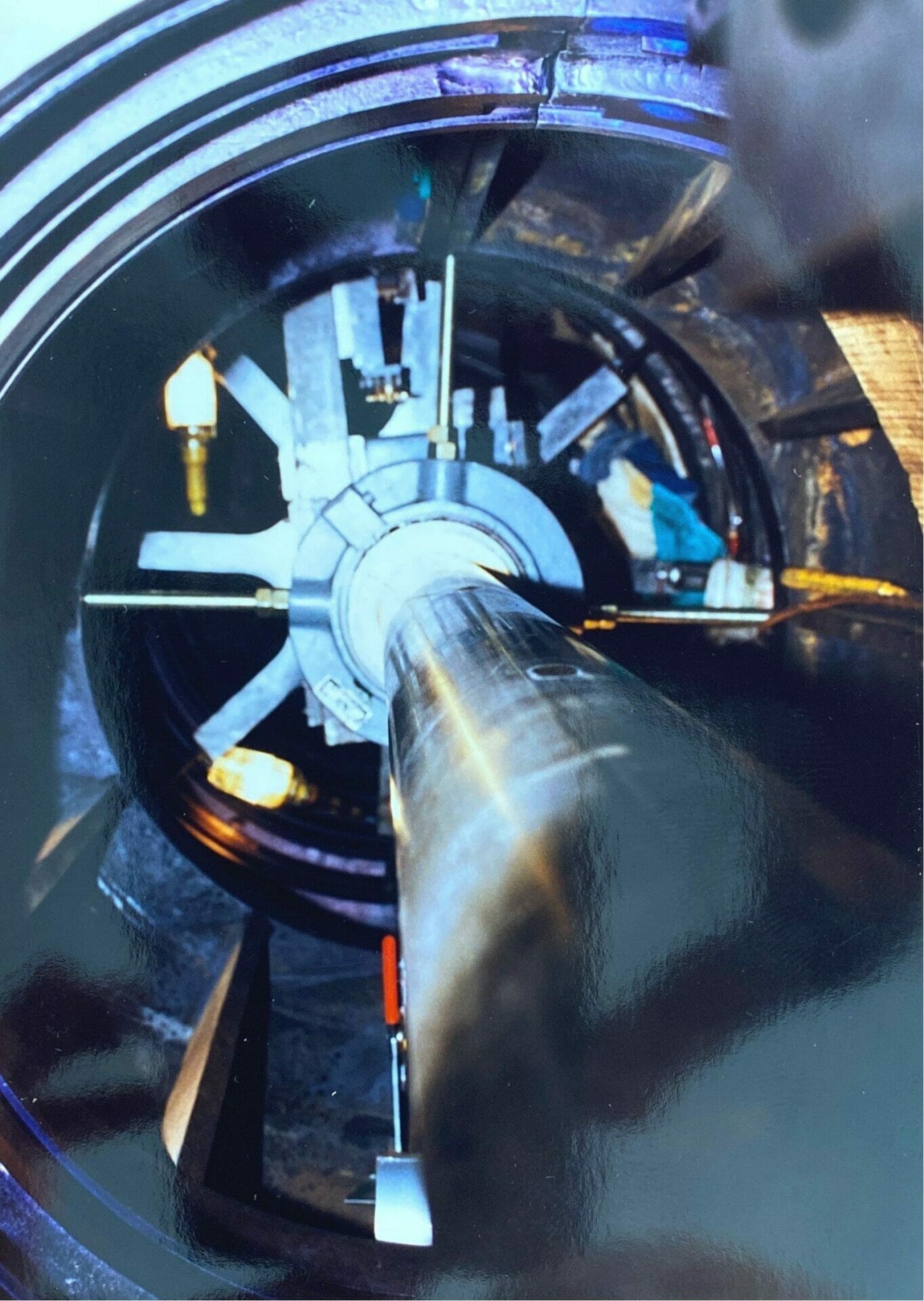

The PGAS deploys the most experienced team of gas turbine alignment specialists in the world. We bring decades of combined work experience at companies such as General Electric and Siemens and have serviced power generation machines across every continent. We specialize in optical alignments with doweling and also provide laser alignments using the latest technology.

Tradition & Technology

With over a century of combined experience and a long history of excellence in providing innovative alignment solutions for the power generation industry, the PGAS team has experience with both old and new generations of turbomachinery and related technology. From minor repair work to whole outages, PGAS offers comprehensive services to get your job done efficiently and with precision.

Get specialized optical and laser alignment and machining services

Experience You Can Trust

At PGAS Inc., our skilled technicians bring experience to every project, ensuring sound engineering decisions and exceptional results. We specialize in Optical Internal Alignments of gas turbines, offering expertise across various turbine models, including F5, F6B, F6FA, F7FA, F7FB, and more. Our comprehensive services include doweling, where we supply all necessary vertical dowels, horizontal body bounds, shims, and gibs for precise bearing alignment.

In addition to optical alignments, we perform Laser Internal Alignments and provide extensive on-site machining capabilities for gas turbines. From valve stud drilling and boring bar machining to flange facing and seal key machining, our team is equipped to handle the most complex challenges. With a commitment to precision and reliability, we are confident that our experience will exceed your expectations and keep your power generation systems operating at peak efficiency.

Our APPROACH

Ready to make the most of planned outages

Reduce the risk of unplanned downtime?

If you are planning a Major Outage on your GE gas turbine and are in need of an Internal Alignment, then PGAS should be your first choice. PGAS runs a turn key operation for Internal Alignments following OEM specs.

PGAS provides the following services for the Internal Alignment process:

- Provide As-found readings

- Advise all corrections needed per Unit specific OEM Alignment Diagram

- Corrections will include casing to casing, upper half to lower half casing, out of roundness, and bearing adjustments

- Orchestrate any and all moves of the casings and bearings

- Redoweling of all existing dowel holes after casing moves

- (Including Radial Doweling TIL 1617 and TIL 1819)

- Provide all new machined hardware (dowels, body bounds, shims, gibs, etc.)

- Spot Facing each casing after moves

- Three Point check

- Final readings with Full Report of all corrections, final positioning of the unit, and machined parts.